The Next Frontier in High-Temperature Materials

NASA’s innovative development of GRX-810 marks a seismic shift in the realm of 3D-printable metals, especially designed for aerospace and high-performance engineering. Most importantly, this breakthrough alloy can withstand extreme heat and stress, thereby redefining the limits of printable materials. Because of its exceptional durability, GRX-810 stands poised to revolutionize applications from jet engines to rocket components.

Besides its remarkable heat resistance, GRX-810 is a testament to the power of advanced engineering and material science. It not only pushes the envelope in performance but also opens new avenues in additive manufacturing techniques. Therefore, this technology encourages broader applications in both commercial and industrial sectors, closely aligning with the strategic directions highlighted in various discussions on NASAs innovations such as those featured in NASA’s YouTube insights.

Why GRX-810 Is a Game-Changer

Until recently, additive manufacturing was restricted by a lack of cost-effective materials that could endure extreme thermal conditions. Most importantly, existing alloys were either unsuitable for high-temperature applications or too expensive to be practical. Because GRX-810 can survive temperatures of over 2,000°F while maintaining its integrity, it fills a crucial gap in material science for aerospace needs. Furthermore, its unique composition ensures both flexibility and strength under mechanical stress.

The innovation behind GRX-810 lies in its engineered resilience. In comparative tests, this alloy outperforms conventional metals by lasting thousands of times longer. Transitioning from theoretical potential to practical application, NASA’s research displays a perfect blend of computational modeling and experimental validation; as noted on NASA Spinoff, this material is a tangible representation of future engineering breakthroughs.

Behind the Science: Alloy Composition and Manufacturing

The secret to GRX-810’s superior performance is its unique alloy composition. The primary metals—nickel, cobalt, and chrome—are enhanced with a ceramic oxide coating on every powdered particle. This oxide dispersion strengthening (ODS) method not only increases heat resistance but also significantly improves the alloy’s lifespan. Most importantly, such a coating ensures that the material can perform under severe conditions without degradation.

In addition, a computational approach was used to develop GRX-810 from the very beginning. Because this approach sped up the design process and allowed for rapid iterations, the alloy was optimized long before physical prototypes were produced. Therefore, advanced digital modeling tools played a crucial role in fine-tuning the characteristics of the alloy, making it ready for real-world high-temperature challenges. More details on these innovative processes can be explored in related resources on Global People Daily News.

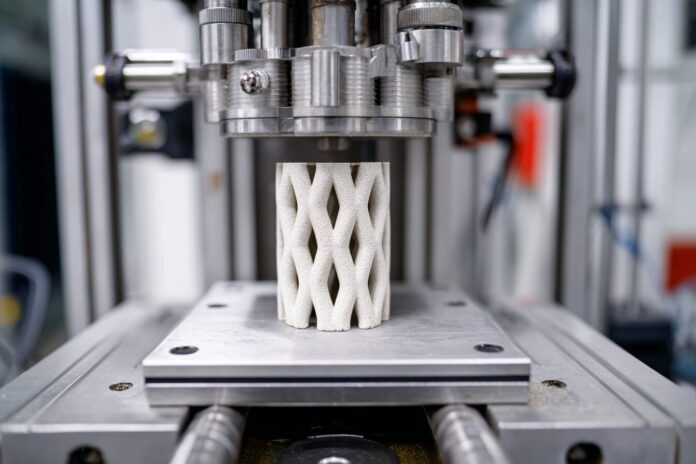

3D Printing: More Than Just Manufacturing

The transformation of metal manufacturing through 3D printing is both revolutionary and practical. With a process that integrates laser fusion layer-by-layer, engineers can directly incorporate nano-oxides into the metal matrix while printing. Most importantly, this integration not only molds the part but also enhances its microstructure and overall performance. This method is a paradigm shift over traditional manufacturing methods.

Because this technology embeds improvement into the printed components, the parts exhibit superior durability and reliability. In essence, each printed component is optimized at the microscopic level, delivering endurance under incredible thermal and mechanical stress. As highlighted in NASA’s YouTube presentation, this technique is setting new benchmarks in 3D printing, making it a cornerstone for future aerospace projects.

Key Performance Advantages

The following performance metrics set GRX-810 apart from conventional alloys. Most importantly, it withstands extreme heat, making it indispensable for parts that operate under fiery conditions.

- Extreme Heat Resistance: The material reliably handles temperatures above 2,000°F, which is critical for aerospace engine components. This ensures enhanced safety and performance in extreme environments. [source]

- Unmatched Longevity: With a lifespan that can be up to 2,500 times longer than traditional alloys, maintenance cycles are significantly extended. Because of this, operational costs can be reduced substantially over time. [source]

- Superior Flexibility: Its design enhances flexibility nearly four times over that of earlier nickel-base alloys, reducing the risk of brittle fractures in high-stress scenarios. [source]

- Oxidation Resistance: GRX-810 offers twice the oxidation resistance compared to earlier alloys, a crucial benefit for components frequently exposed to hot gases and reactive environments. [source]

Because of these impressive metrics, GRX-810 sets a new standard in high-temperature engineering. Transitioning from research to real-world applications, this alloy promises a new era of energy efficiency and operational reliability.

Applications: Aviation and Space Exploration

GRX-810 has a wide range of applications, particularly in aviation and space exploration. Engine injectors, combustors, turbines, and other parts in the hot section of engines benefit significantly from its high performance. Most importantly, these components are crucial for ensuring that both spacecraft and commercial aircraft perform safely under extreme conditions.

Because the alloy endures high stress and temperatures, operators may witness lower operating costs and improved fuel efficiency. Therefore, its adoption can lead to more sustainable flight operations and a reduction in overall environmental impact. Moreover, the continued use of this material in projects is expected to drive further innovations in the aerospace industry, as noted by NASA’s features on industry pioneers.

Innovation Through Collaboration

GRX-810 is the result of robust collaboration among a diverse group of experts. Beyond NASA’s internal research teams, multiple research centers—such as Glenn, Ames, and Marshall Space Flight Centers—contributed to the project. Most importantly, academic partners like The Ohio State University provided critical insights that accelerated the development process.

Because of such collaborative efforts, rapid prototyping, testing, and validation became achievable milestones. This multidisciplinary approach ensured that GRX-810 was not only scientifically sound but also industrially viable, setting a strong foundation for broader market adoption. As a result, this collaboration model is now an example for future multi-institutional partnerships in groundbreaking technological research.

What This Means for the Future

GRX-810 is a breakthrough that paves the way for future innovations in aerospace and beyond. Most importantly, it not only meets the current demands for high-temperature materials but also creates opportunities for entirely new applications. Because of its revolutionary qualities, industries beyond aerospace may soon benefit from its enhanced performance and longevity.

Therefore, technology licensing and subsequent commercial applications are on the horizon. Companies in sectors like commercial jet propulsion, hypersonic transport, and even industrial equipment manufacturing are anticipated beneficiaries. Besides that, GRX-810 exemplifies how advanced materials can drive sustainability and efficiency in high-demand environments, a topic elaborated in various industry publications.

Conclusion: NASA’s Material Revolution

This breakthrough in printable metals is far more than a technical achievement; it represents a blueprint for future innovations. Most importantly, NASA’s pioneering use of computational modeling and advanced 3D printing techniques signals new directions in material science. Because of these developments, stronger and smarter materials are now within reach for a variety of challenging applications.

In conclusion, as the aerospace industry—and indeed, many other sectors—embrace GRX-810, we are witnessing the dawn of a material revolution. Therefore, this innovative alloy is poised to transform not only how we build engines and vehicles but also how we approach the challenges of extreme environments. The future of engineering looks brighter with each new advancement in this revolutionary field.